Language EnglishРусский язык

加入收藏在线留言网站地图欢迎光临山东胜沃塑料机械科技有限公司官网!

400-008-1116

PET注塑机由塑化部分和注塑部分组成;先将PET物料加热塑化,再经注塑部分注塑成型。随着人们生活质量的提高,对塑料制品的品质也越来越高。PET物料的熔点高,制品透明度高且轻便,目前PET瓶的应用成几何级数的增长,广泛应用于饮料类、医药类和日用品类等领域。

特点介绍:

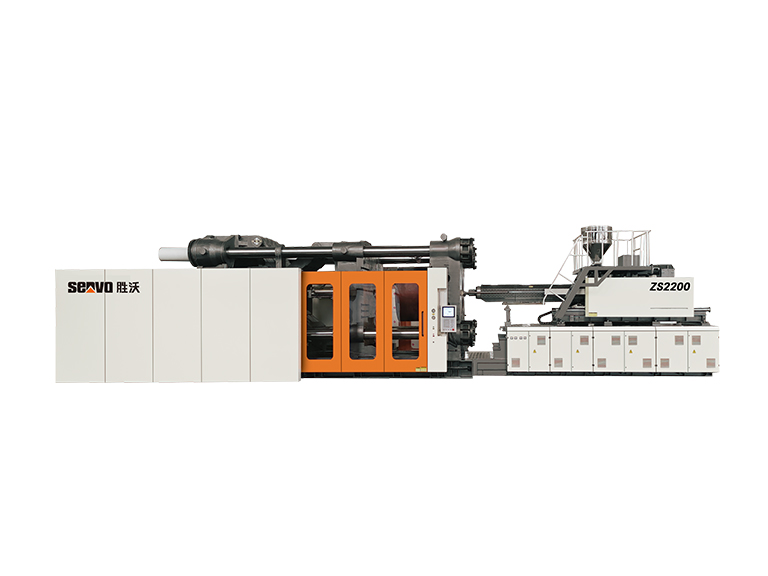

1、ZP 致胜 PET专用机主要适用于 PET瓶胚及 PET包装类行业,配置大功率动力,大扭距马达,大顶出力油缸。

ZP PET special machine is mainly suitable for PET bottle embryo and PET packaging industry, equipped with high power, large torquemotor and large jacking oil cylinder.

2、PET专用螺杆大长径比设计,兼顾塑化效率与塑化效果。A杆配置主要针对收纳盒、酒盒包装等

PET 原材料一次成型制品,B 杆配置主要 针对 PET瓶胚类产品。

The PET dedicated screw design with a large L/D ratio balances eficiency and eftectiveness of plasticization. the A rod configurationis mainly for products made from raw materials in a single molding process, such as storage

boxes and wine boxes, while the B rodconfiguration is mainly for PET preform products

3、料筒标配陶瓷加热圈,适配PET材料高温需求与加热高稳定性。标配数控背压阀,方便制品工艺调整。

The cylinder is equipped with ceramic heating ring as standard, which adapts to the high temperature demand and

high heatingstability of PET material., Standard numerical control back pressure valve, convenient for product process adjustment.

4、客户可根据产品克重及成型周期要求选择不同射台与合模部分进行组合。

According to the product weight and molding cycle requirements, customers can choose

diferent shooting platform and die-closingparts for combination.

5、可选配电动储料装置与开储同步功能,大幅缩短成型周期,全系标配四周顶出强制复位功能。

Optional electric storage device and open storage synchronization function, grealy shorten the molding cycle, the whole systemstandard around the ejection forced reset function.

| 技术参数表 SPECIFICATION | ZP170/IU640 | ZP220/IU1000 | ZP280/IU1400 | ZP350/IU2050 | ZP380/IU2650 | ZP420/IU3050 | ZP480/IU4400 | ZP530/IU5600 | ZP600/IU5600 | |||||||||||||||||||

| 注射部分 INJECTION UNIT | B | B | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | |||||

| 注射容积 Shot Weight |

cm³ |

452 | 677 | 677 |

996 |

1155 | 990 |

1546 |

1759 | 1327 | 2011 | 2270 | 1327 | 2270 | 2545 | 2032 | 3261 | 3613 | 2032 | 4085 | 4503 | 2032 | 4085 | 4503 | ||||

| 注射量(PET) Injection Weight | g | 560 | 840 | 840 | 1235 | 1435 | 1228 | 1920 | 2182 | 1646 | 2502 | 2820 | 1646 | 2820 | 3155 | 2520 | 4045 | 4480 | 2520 | 5065 | 5585 | 2520 | 5065 | 5585 | ||||

| 螺杆直径 Screw Diameter | mm | 50 | 55 | 55 | 65 | 70 | 60 | 75 | 80 | 65 | 80 | 85 | 65 | 85 | 90 | 75 | 95 | 100 | 75 | 100 | 105 | 75 | 100 | 105 | ||||

| 螺杆长径比 Screw L/D Ratio | Sc | 25 | 25 | 25 | 26 | 25 | 25 | 26 | 25 | 25 | 26 | 25 | 25 | 26 | 25 | 25 | 26 | 25 | 25 | 26 | 25 | 25 | 26 | 25 | ||||

| 注射速率 Injection Rate | cm³/s | 245 | 298 | 272 | 350 | 398 | 380 | 575 | 655 | 383 | 585 | 660 | 446 | 575 | 645 | 530 | 670 | 730 | 530 | 800 | 880 | 558 | 800 | 880 | ||||

| 注射压力 Injection Pressure | Mpa | 141 | 146 | 176 | 140 | 120 | 165 | 133 | 120 | 172 | 133 | 120 | 172 | 134 | 120 | 168 | 135 | 122 | 168 | 137 | 125 | 168 | 137 | 125 | ||||

| 最大塑化能力(PET) Plasticzation Capacity | g/s | 40 | 53 | 58 | 70 | 77 | 70 | 110 | 130 | 90 | 130 | 140 | 90 | 140 | 160 | 117 | 185 | 200 | 117 | 220 | 250 | 122 | 220 | 250 | ||||

| 最大螺杆转速(电动储料) Max Screw Speed | rpm | 200(250) | 200(250) | 220/160(250) | 200/160(250) | 200/160(250) | 200/135(250/220) | 170/135(240/220) | 170/135(240/170) | 175/135(240/170) | ||||||||||||||||||

| 合模部分 CLAMPING UNIT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

| 合模力 Clamping Force | Kn | 1700 | 2200 | 2800 | 3500 | 3800 | 4200 | 4800 | 5300 | 6000 | ||||||||||||||||||

| 最大移模行程 Clamping Stroke | mm | 430 | 500 | 550 | 660 | 700 | 730 | 780 | 850 | 900 | ||||||||||||||||||

| 拉杆内间距(WxH) SpaceBetweenTie Bar(WxH) | mm | 470*470 | 560*530 | 610*570 | 710*680 | 730*710 |

760*730 |

8200*780 | 860*820 | 920*880 | ||||||||||||||||||

| 最大模板距离 Max. Daylight | mm | 940 | 1050 | 1200 | 1410 | 1450 | 1530 | 1580 | 1750 | 1800 | ||||||||||||||||||

| 容模厚度(最小-最大) MaxMold Height ( Min-Max) | mm | 145-510 | 160-550 | 180-650 | 250-750 | 250-750 | 280-800 | 280-800 | 320-900 | 320-900 | ||||||||||||||||||

| 顶出行程 Ejector Stroke | mm | 120 | 140 | 160 | 180 | 180 | 200 | 220 | 220 | 260 | ||||||||||||||||||

| 最大顶出推力 Ejector Force | Kn | 58 | 68 | 99 | 125 | 125 | 138 | 152 | 152 | 182 | ||||||||||||||||||

|

电控部分 CONTROL UNIT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 系统压力 System Pressure | Mpa | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | ||||||||||||||||||

| 油泵电机功率 Pump Motor Power | Kw | 26 | 31 | 37 | 50/55 | 50/55 | 55 | 65 | 65/50+31 | 37+37/50+31 | ||||||||||||||||||

| 储料电机功率(选配)❈ Power of storage motor(optiona)❈ | Kw | 16(一体式直驱) | 21(一体式直驱) | 21/35(一体式直驱) | 35/47(一体式直驱) | 35/50(一体式直驱) | 35/55(一体式直驱) | 47/65(一体式直驱) | 47/65(一体式直驱) | 47/65(一体式直驱) | ||||||||||||||||||

|

电热功率 Heater Power |

Kw | 17 | 22 | 22/28 | 25/35 | 30/40 | 30/45 | 40/50 | 40/55 | 40/55 | ||||||||||||||||||

| 温度控制区数 No.of Heater Control Zone |

Zone |

5 | 5 | 5/6 | 5/6 | 5/6 | 5/6 | 6/6 | 6/7 | 6/7 | ||||||||||||||||||

| 其他 OTHERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

| 油箱容量 Oil Tank Capacity | L | 220 | 300 | 350 | 420/500 | 460/500 | 500 | 600 | 700 | 700 | ||||||||||||||||||

| 理论重量(约) Machine Weight | T | 5 | 6.5 | 8.5 | 12.5 | 14 | 15 | 18 | 21 | 24 | ||||||||||||||||||

| 外型尺寸(LxWxH) Machine Dimension (LxWxH) | M | 5.2x1.4x2 | 5.8x1.5x2 | 6.3x1.6x2.2 | 7.3x1.7x2.3 | 7.7x1.8x2.4 | 8x1.8x2.4 | 8.6x1.9x2.4 | 9.2x2x2.4 | 9.7x2.1x2.4 | ||||||||||||||||||

本网站所有技术参数仅供参考,本公司保留修改技术参数的权利,恕不另行通知。All technical parameters of this website are for reference only. The company reserves the right to modify the technical parameters without notice.

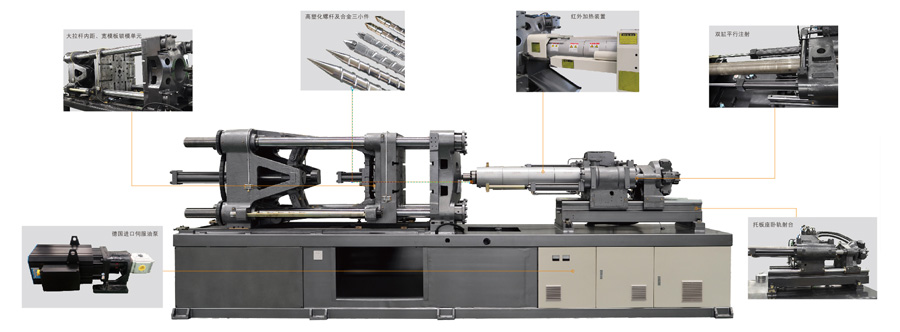

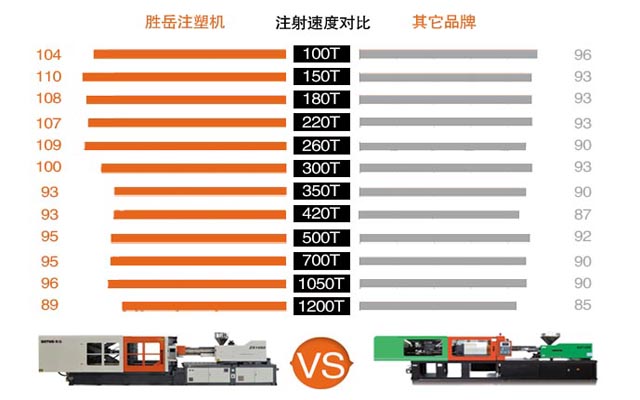

高排量的液压系统设计,动力系统加大,注射速度比同类型产品提高15%,模循环周期缩短10-15%,全面提升注塑机表现,可满足高标准的成型要求

油路板分布在各执行元件位置,响应速度快,动态性能好,注塑过程更快速,产品成型更好

注射单元采用模组化的托板座设计,一线式双缸平衡注射装置,使螺杆在注塑过程中受力均匀,显著提高射胶稳定性,使料筒定位更加准确

高刚性的宽模板设计,配合高安全系数的拉杆,整体提升合模结构的刚性及稳定性

伺服驱动器在锁模保压冷却等阶段能输出最大压力但保持速度接近零速,因而功率消耗小,更节能

料筒采用纳米远红外高效节能加热装置,改善了传统加热圈电热转换效率低、热传导率低、表面温度高“两低一高”缺点,比传统加热圈节能30%-40%

控制面板采用彩色屏幕,实时监测生产进程,并显示各种故障诊断,操作更省心

人性化工艺参数设置,设置急停开关,动作全面监控,保护工作人员人身安全